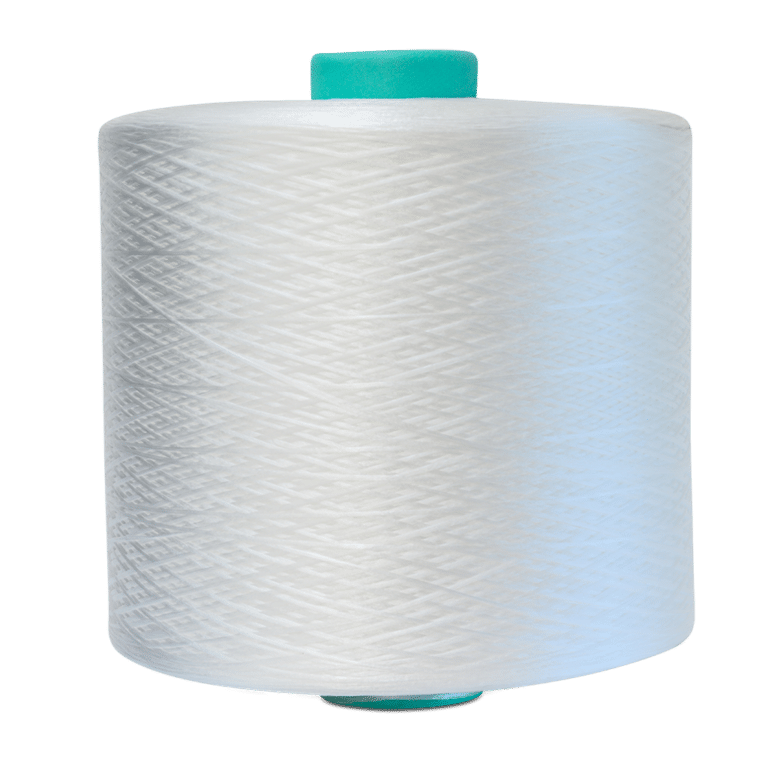

Innovative Commingled Yarns

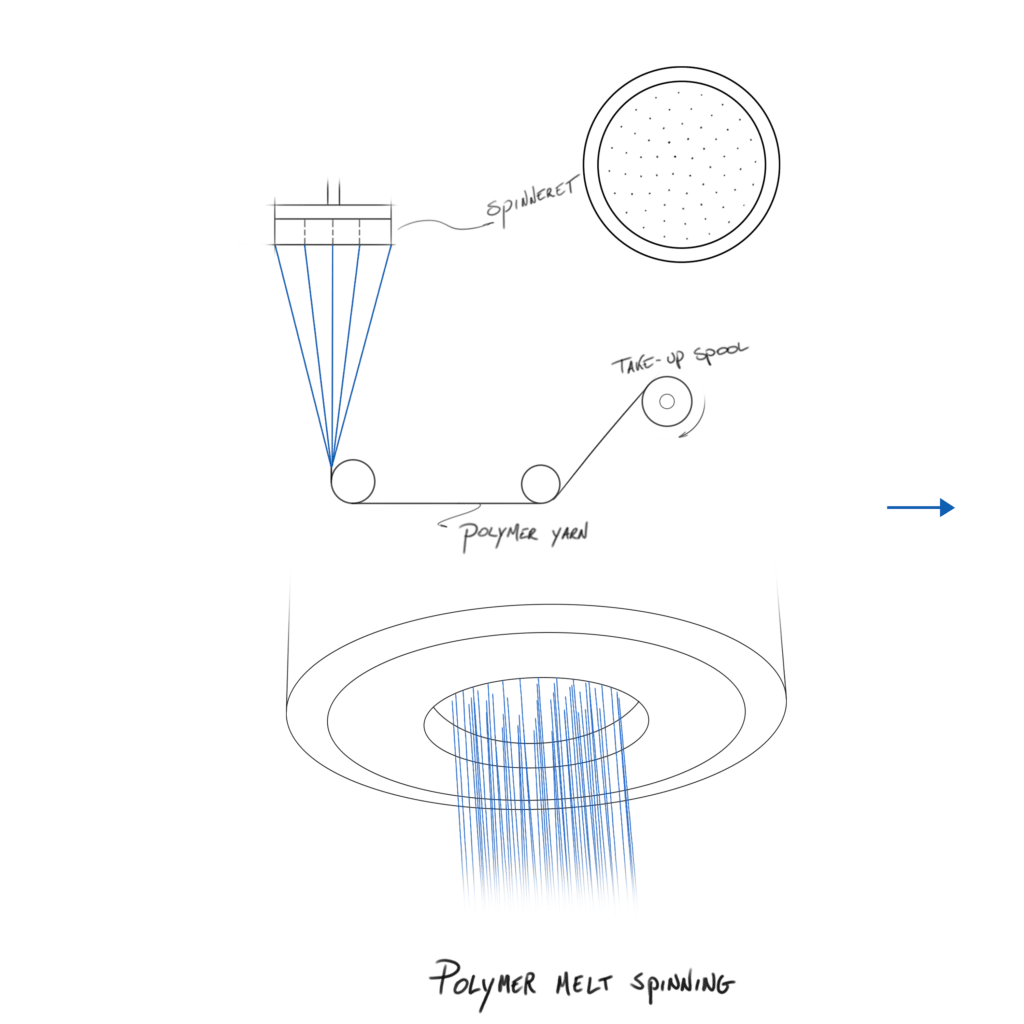

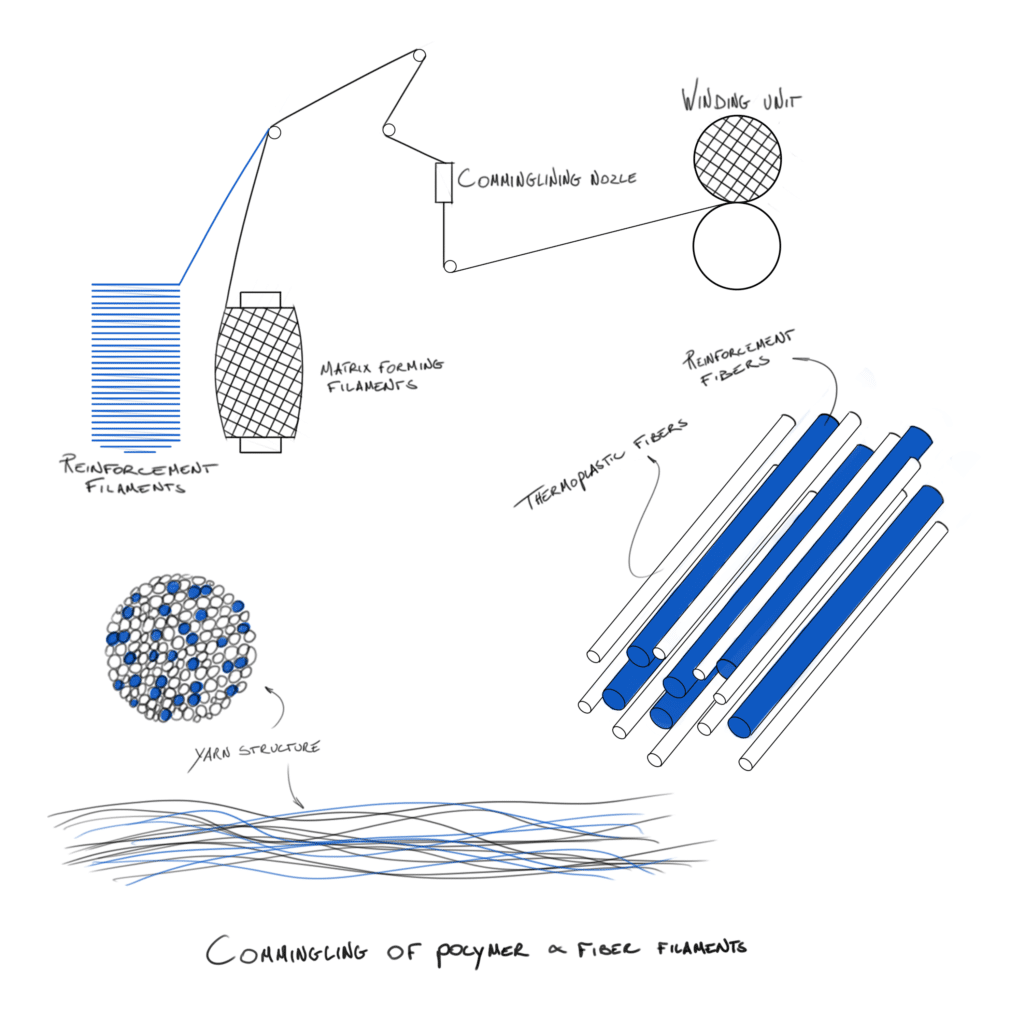

COMFIL develops and produces thermoplastic composites made with commingling technology. Commingled yarns can be made of any endless reinforcement fiber material combined with any thermoplastic polymer processable for multifilament yarn.

Sustainable Thermoplastic Composites

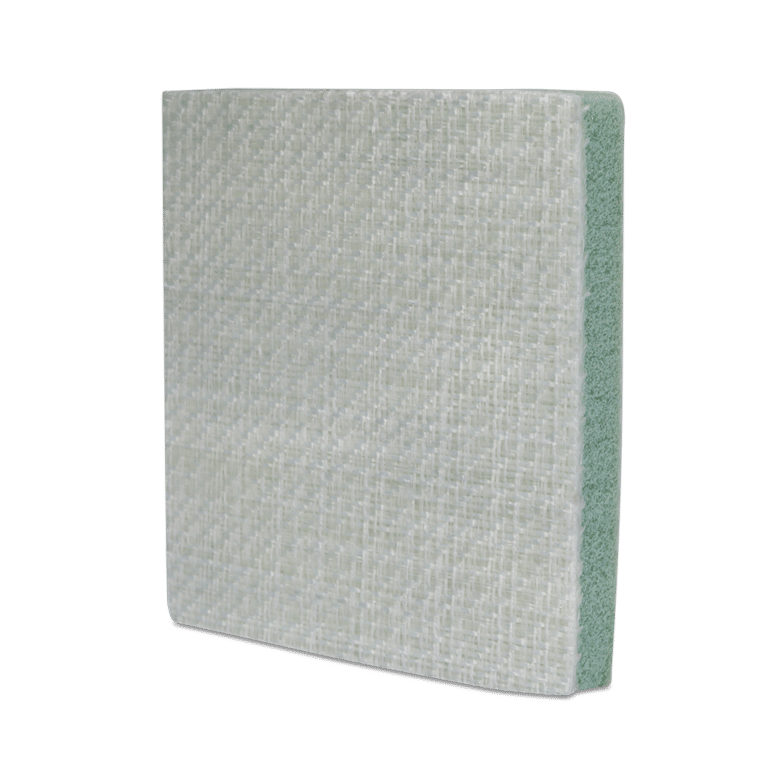

COMFIL is offering a variety of high quality composites suitable for the most demanding applications. We work closely with our customers and develop new innovative products and solutions to meet any specialized customer requirement or demand in the market.

COMFIL PROCESS ADVANTAGES

- Recyclability

- Flexibility

- Strength

- Purity

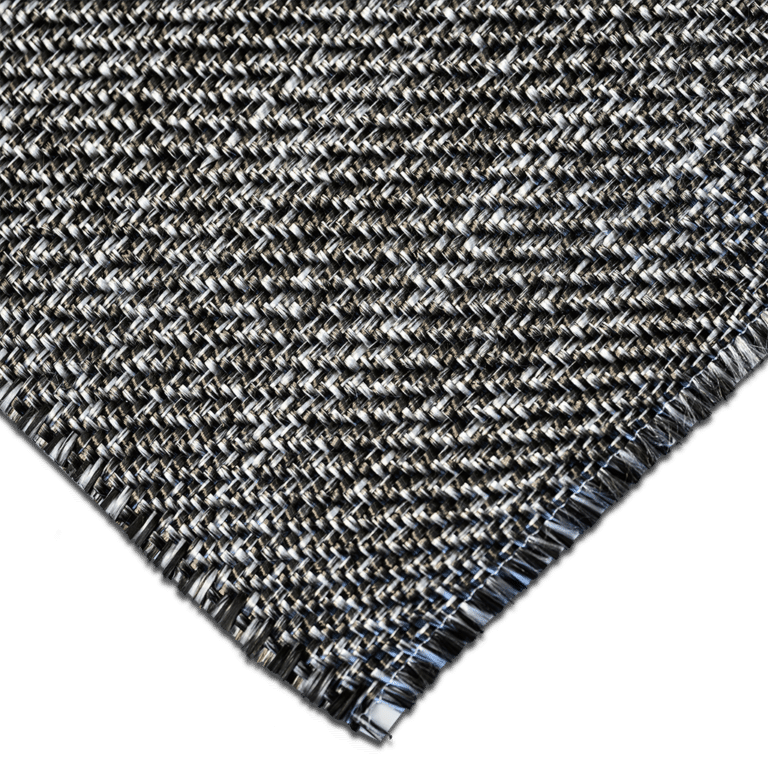

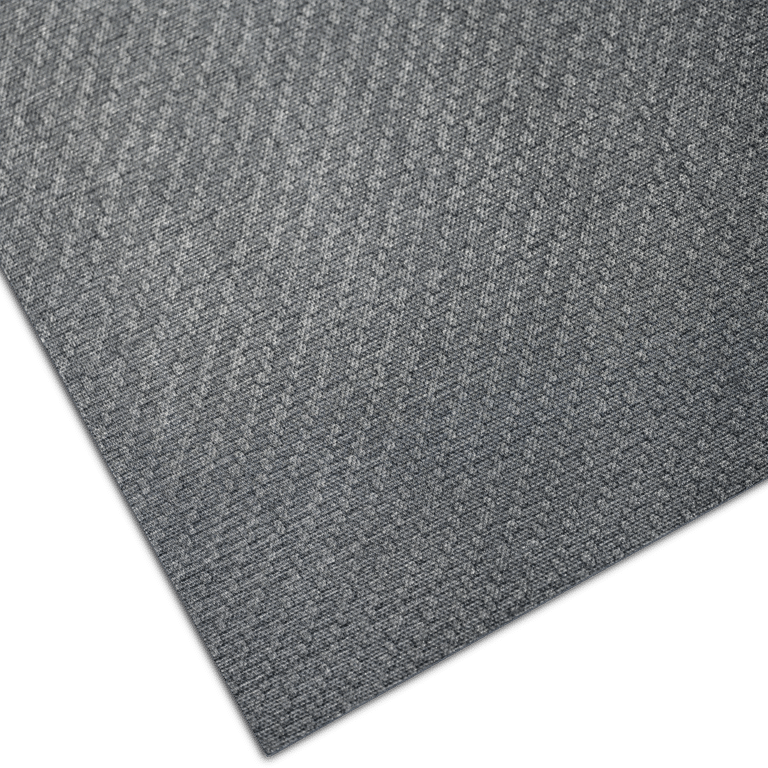

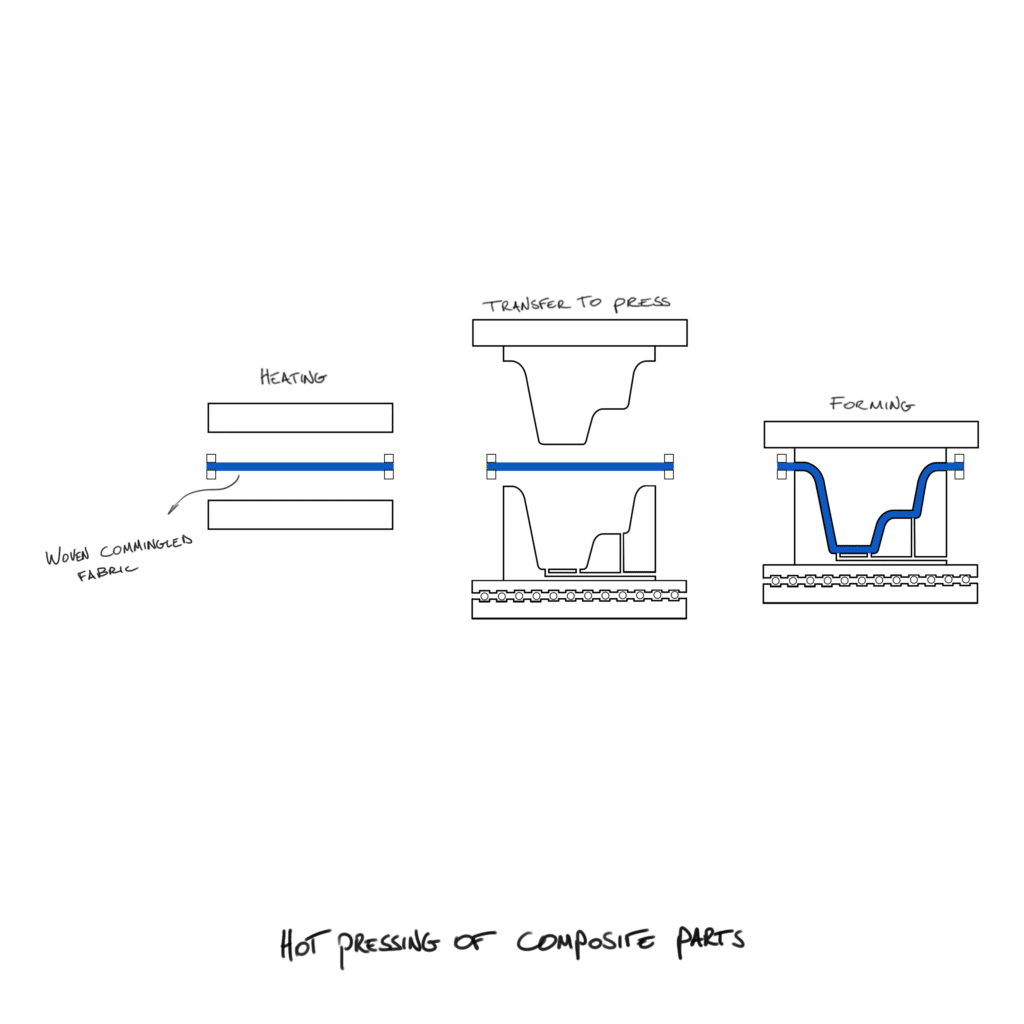

COMFIL offers flexible and customizable hybrid materials which are reinforced with specific fibers and designed to withstand different temperatures, chemicals, and wear.

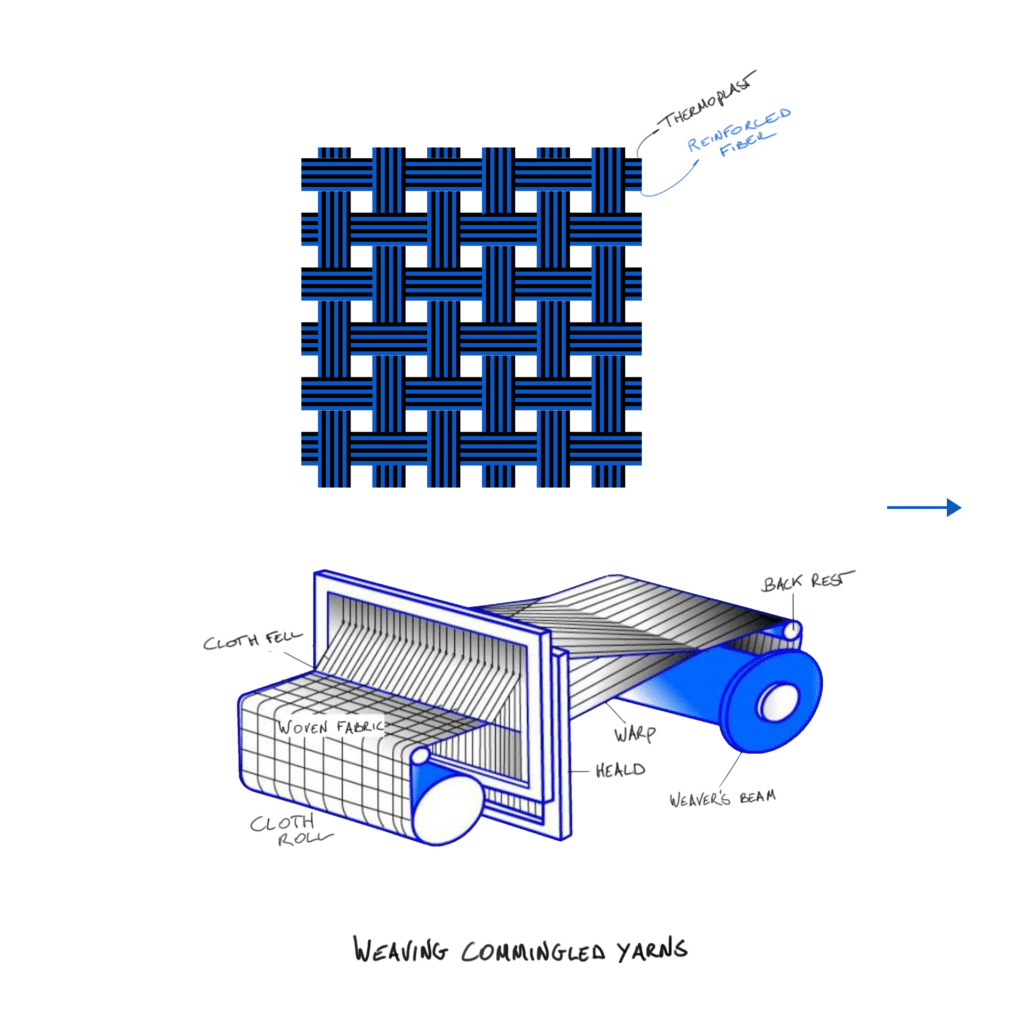

In a fast development process, COMFIL offers the possibility to use matrix materials that are not available as thermoset matrix. Our materials have superior durability, good impact behavior, and have good distribution of fibers and matrix material. They also have excellent drapeability and can be easily fabricated into fabrics, winded, or pultruded. Our materials have high purity, outstanding shelf life, can be recycled efficiently and do not use solvents.

Visit our product portfolio or contact us to learn more.