COMFIL offers fabrics woven from our commingled yarns. The melting matrix polymer is already mixed into the reinforcement fibers via the commingling process resulting in a fabric, that can be moulded directly into a desired shape.

Commingled fabrics are easy to process into fully shaped and consolidated thermoplastic composites by using pressure and heat.

· Choice of fiber and polymer mix

· Excellent drapeability

· Excellent possibilities for 3-D compression moulding

· Choice of weaving style and fiber direction

· Width of 65 -220 cm

· For large volumes we can offer width up to 300 cm

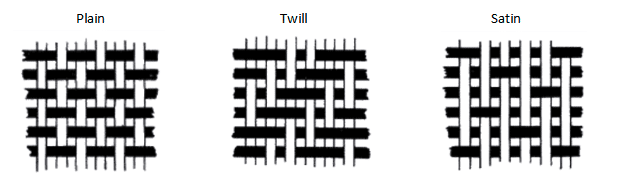

| Property | Plain | Twill | Satin |

|---|---|---|---|

| Good stability | B | C | D |

| Good drape | D | B | A |

| Low porosity | C | B | A |

| Smoothness | D | C | A |

| Balance | B | B | D |

| Symmetrical | A | C | E |

| Low crimp | D | C | A |

| Cosmetics | B | A | D |

| Ease of use | A | A - B | C - D |

(Key: E=very poor, D=poor, C=acceptable, B=good, A=excellent)

© 2024 Comfil – Designet af Aveo web&marketing